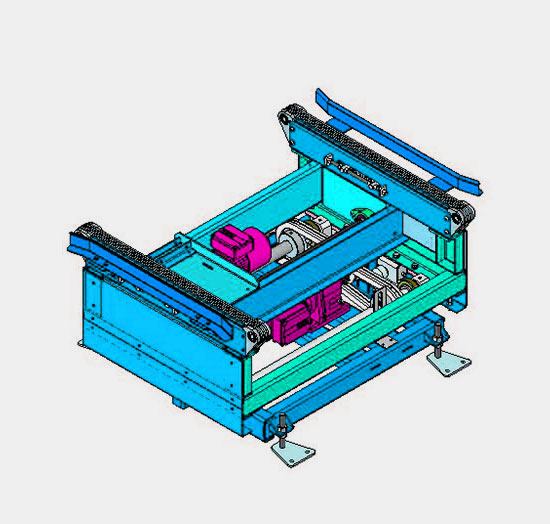

Pallet chain lift transfer unit:

One. main structure and features:

Jacking mechanism: the base type deceleration motor is placed in the middle of the welding type bottom frame with adjustable feet. The two shafts are connected by the bearing seat and bottom frame on both sides. The two shafts are connected with the motor through the transmission chain. Each shaft and both ends are equipped with needle roller bearing crank arm to form the jacking structure.

Load shifting mechanism: adopt chain machine, the specific structure is the same as the foregoing.

Accessory device: photoelectric support (lift two positions, in place detection).

Purchased parts configuration: reducer motor SEW, chain for hangzhou donghua, bearing with seat TR, ha shaft for bearing.

Surface coating: steel wire brush, sand paper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 90 m.

Two. Main performance and parameters:

| Description Two row conveyor chain c10b-2 Polyethylene chain holder Frame steel 120 x 70 x 15 x 4 mm CAM lifting, travel 70mm Intermediate device type |

Type | |

Standard | Standard |

Length(mm) | L = matching chain machine center distance B - 100 |

Height (mm) | H(min)≥550(with chain machine H=600) |

Chain pitch B (mm) | 650 ≤ B ≤ 1750(SEW motor) 550 ≤ B ≤ 1750(city motor) |

Motor power P (kw) | Lifting :0.75 ~ 1.5 Conveying :0.75 ~ 1.5 |

Line speed V (m/min) | V=12 V=16 V=18 |

Lifting time (S) | 2.3(single stroke) |

Standard load (Kg) | Max ≤1000Kg |

Maximum load (Kg) | Max ≤1500Kg |