Pallet RGV:

One. main structure and features:

Guide rail: adopt two aluminum alloy guide rail as the shuttle's walking track, with safety buffer blocking at both ends of the track.

Table carrier: roller table machine/chain machine can be installed and configured according to actual project requirements.

Walking mechanism: high hardness and wear-resisting polyurethane coated walking wheel, driven by motor.

Guide: single side guide wheel guide, reduce the requirement of parallelism of both side guide.

Purchased parts configuration: reducer motor SEW, chain for hangzhou donghua, bearing with seat TR, ha shaft for bearing.

Surface coating: steel wire brush and sandpaper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 80 m.

Two. Main performance and parameters:

| |

Description Standard aluminum rail h * w = 120 * 90 mm, L '6 m or less; Two non-standard aluminum rail length period of each side with a staggered arrangement; Standard shuttle car for tray 1 ~ 1.2 m; Conveying height: 542 H(chain) 850, 535 H(roller) 850; Rail leg, rail bar spacing is designed according to the standard design; Standard three-phase four-star flexible one-piece sliding contact line, the two ends with taut, fixed splint spacing F = 400 mm; After running for one month, all fasteners must be lowered and re-tightened. The collector adopts double head collector; Infrared laser ranging or bar code control; Machine chain conveyer surface from the default height 145 mm at the bottom of the rack, roller machine for 138 mm, if not, when using the BOM below to increase or decrease to standard height; Transportation equipment should be separately below. | |

Type

| |

Name | Description |

Track spacing WG(mm) | WG = 1000 (standard spacing), non-standard length of a section of each side end |

Pull rod spacing G (mm) | At both ends of G0 = 500, G = 2000 uniform distribution, terminal shall not exceed 2000 |

Conveyor width B or W (mm) | 850≤B≤1050,1020≤W≤1220 |

Support spacing Z (mm) | Z0=300 at both ends, Z=800 evenly distributed, the final section shall not exceed 800 |

Pallet length L0(mm) | If L0 1200 or less (L0 > 1200, track spacing to non-standard) |

Tray width W0(mm) | 1000≤ W0≤1200 or less or less (other values corresponding to modify the bottom frame and leg) |

Width of tray foot D(mm) | D≥80 (for chain conveyor) |

Conveyor length LS(mm) | LS≥WG+500 |

Safe distance between docking devices K (mm) | 10≤K≤15 |

Conveying height H0(mm) | H0≤800 (inspect the anti-dumping ability of the goods) |

Lower jaw height H (mm) | 542≤H(chain)≤850,535≤H(roller)≤850; |

Distance S1 (mm) from center to side of no-power box | S1=810 |

There is electricity box side center to edge distance S2 (mm) | S1=1476 |

Equipment general S (mm) | S=S1+S2=2286 |

Limit safe cut-off distance S0 (mm) | S0=500+Switch mounting position≈750 |

Stroke E (mm) | As per project requirements |

Total track length L (mm) | L=E+S+S0*2 |

Motor power | P=2.2B; |

Conveying speed V (m/min) | V≤160 |

Stop precision J (mm) | ±5 |

Bearing capacity M(Kg) | M≤1500 |

Total load (Kg) | 40Kg/m+630Kg+M |

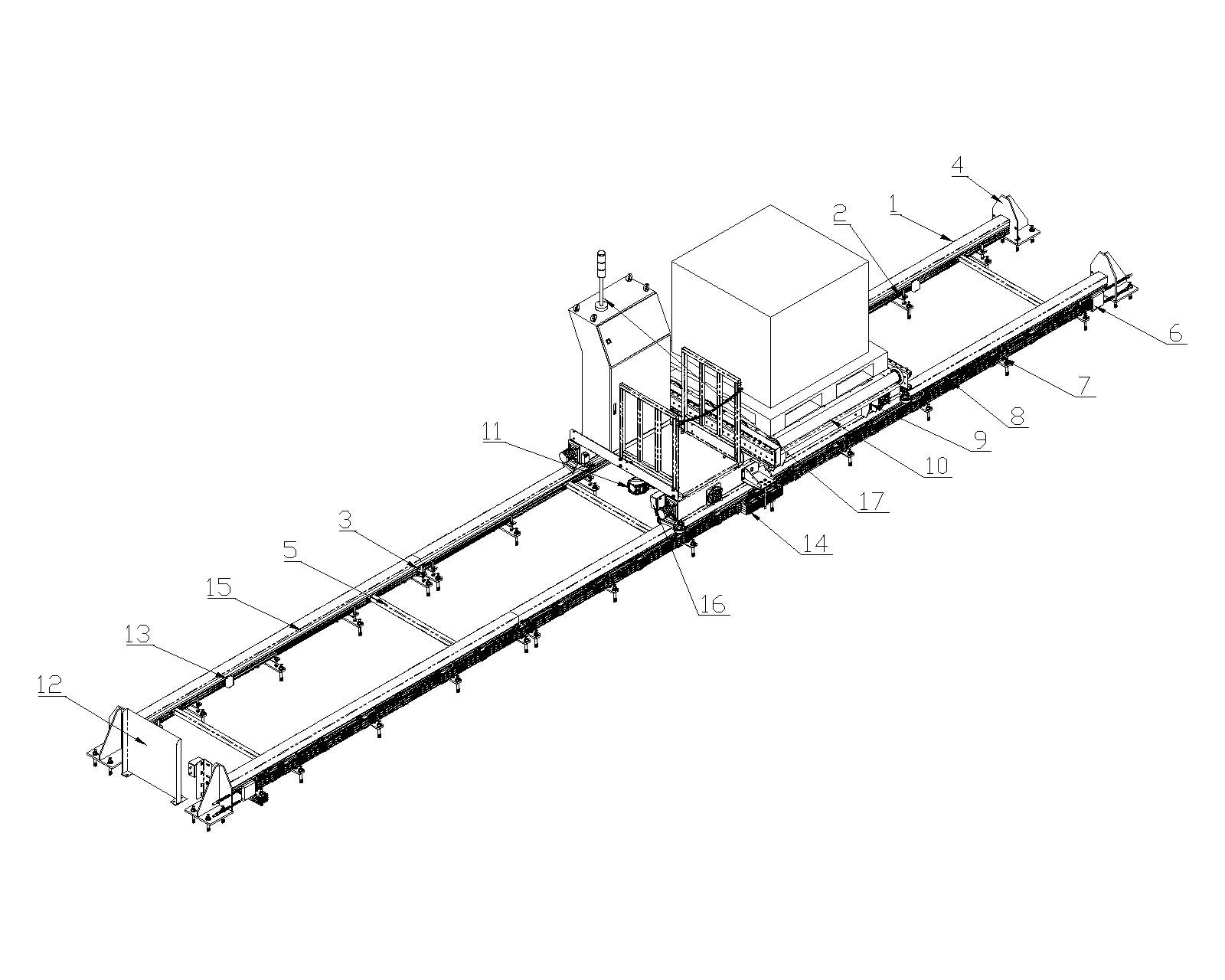

Structural diagram

Order number | Name | Order number | Name |

1 | Aluminum profile track | 11 | Laser rangefinder |

2 | Fixed support | 12 | Ranging reflector |

3 | Connected to a fixed seat | 13 | Power-off protection test plate |

4 | End block | 14 | Collector (double head) |

5 | Track bar | 15 | Location bar code (optional) |

6 | Slide wire tensioner | 16 | Infrared com (optional) |

7 | Flexible one-piece sliding contact line | 17 | Three color lamp |

8 | Fixed splint | ||

9 | Conveyor legs | ||

10 | Shuttle car | ||

Note The drive motor, guide wheel and sliding contact wire shall be installed on the same side; The goods shall not exceed the pallet; 。 laser ranging plate and block the lateral alignment, prevent accident damage to the laser range finder. | |||

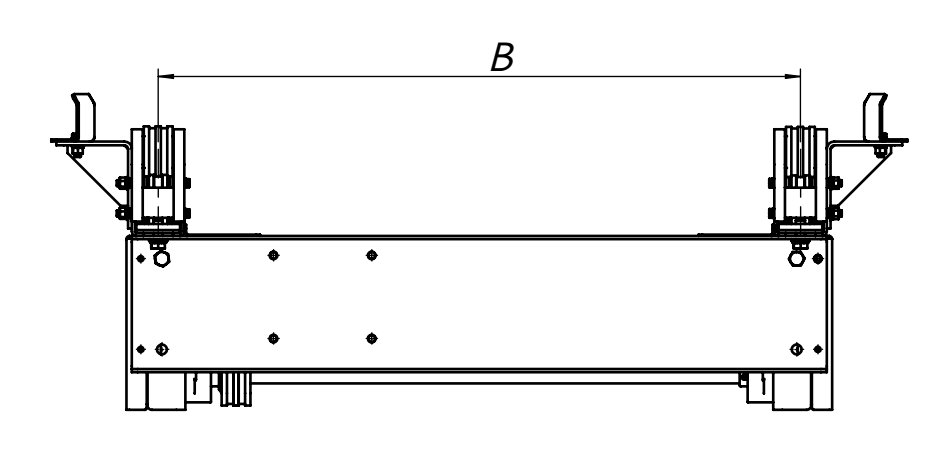

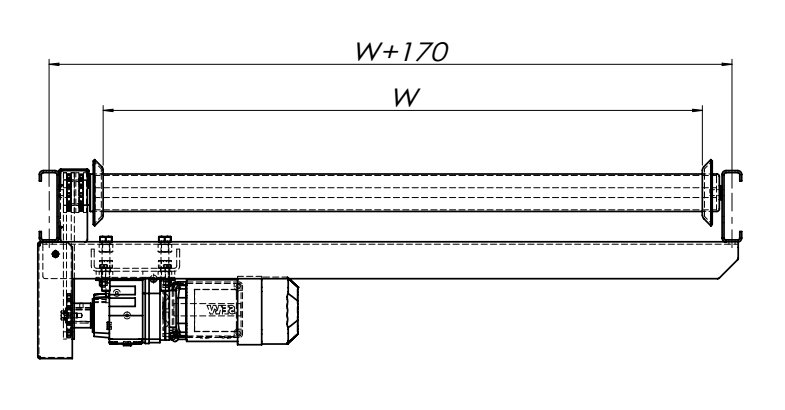

1.1.RGV shuttle car

|

Description Standard RGV linear shuttle car is fixed structure; u Suitable for tray width 1 ~ 1.2m u Excluding transportation equipment and leg. |

1.2.RGV ground orbit module

|

Description u The number of rail adjusting base, RGV rail connecting base, RGV rail pull rod and RGV sliding contact wire connecting assembly is determined by rail total length L; u Total length L=E+S+S0*2; u The number of RGV track spacer is one half of the sum of RGV track adjusting base and RGV track connecting base. |

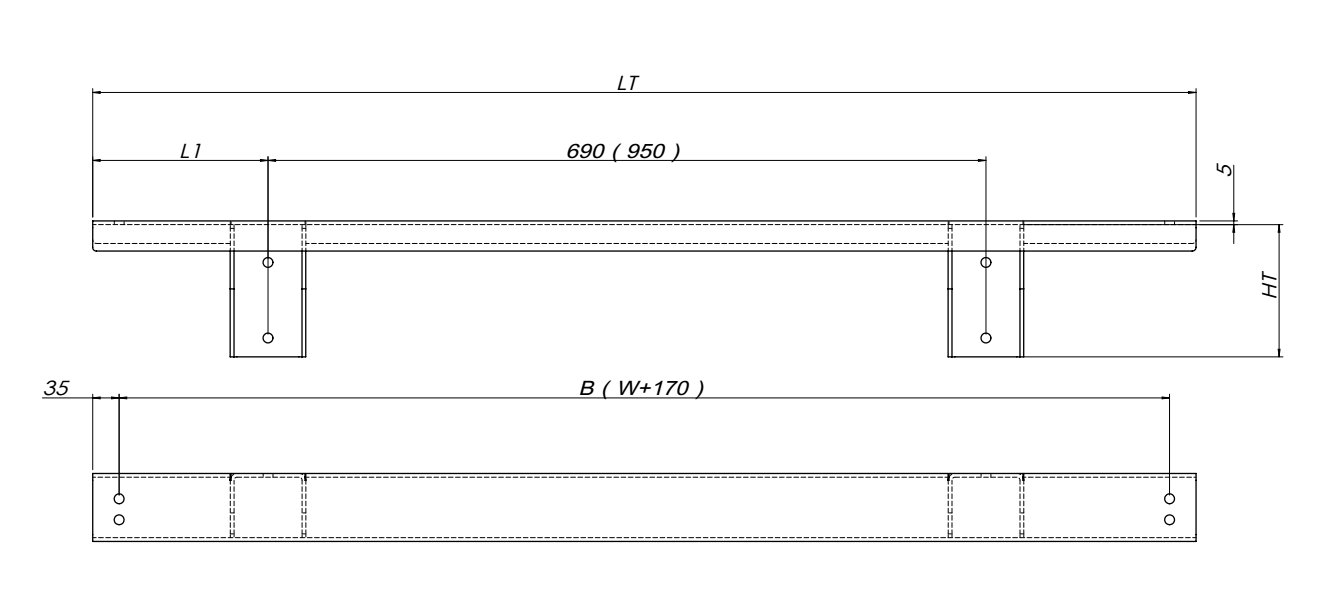

1.3. Supporting legs of RGV conveyor

The supporting leg varies in width and height according to the conveying form of the conveyor. The details are as follows:

Order number | Delivery form | Total length of LT(mm) | Mounting hole spacing JT(mm) | Leg vertical height HT(mm) | L1 | note |

1 | The chain | LT=B+70 | 690 | HT=H-382 | L1=(LT-690)/2 | B is the inner width of the chain |

2 | roller | LT=W+240 | 950 | HT=H-375 | L1=(LT-996)/2 | W is the inner width of roller table |

1.4. Conveying equipment

Standard linear shuttle chain conveyor USES standard chain conveyor (leg height is 0), roller conveyor USES standard roller table. There is no conveying equipment in the table, please refer to the following picture.

1.4.1. Chain machine

1.4.2. Roller machine

1.5. Optional attachments

Optional accessories of electrical components by electronic control options, such as model and standard model of inconsistencies, should be installed according to the actual situation to redesign the board or frame. Select and follow the parts list below.

1.5.1. Optional attachment diagram

Order number | Name | Shown in figure | Electrical components brand model | note |

1 | RGV laser ranging module |

| Lloyd's laser range finder AMS 304i 40 | Select one of the RGV laser ranging module and the RGV code reading module as required by the project |

2 | RGV ranging reflector |

| There is no | Corresponding RGV laser ranging module choice |

3 | RGV code reading component |

| Double blessing sweep dockPCV100-F200-B17-V1D | According to project requirements, select one of the RGV laser ranging module and the RGV code reading module, corresponding to the RGV bar code. |

4 | RGV infrared communication module |

| SICK infrared data transmitter isd400-6111 | Select as needed, corresponding RGV ground infrared communication module |

5 | RGV ground infrared communication module |

| SICK infrared data transmitter isd400-6111 | Select as needed, corresponding to RGV infrared communication module |

1.5.1. List of optional attachments (actually selected according to project needs)

Project number | ||||||||

Order number | coding | Equipment code | Name | Drawing number | unit | quantity | note | |

1 | 22.1.94.0000.0000 | RGV laser ranging module | RGV.01.13 | PCS | One / set | If any | ||

2 | 22.2.91.0000.0000 | RGV ranging reflector | RGV.02.09 | PCS | One / set | If any | ||

3 | 22.1.93.0000.0000 | RGV code reading component | RGV.01.12 | PCS | One / set | If any | ||

4 | 22.1.95.0000.0000 | RGV infrared communication module | RGV.01.14 | PCS | One / set | If any | ||

5 | 22.2.92.0000.0000 | RGV ground infrared communication module | RGV.02.10 | PCS | One / set | If any | ||