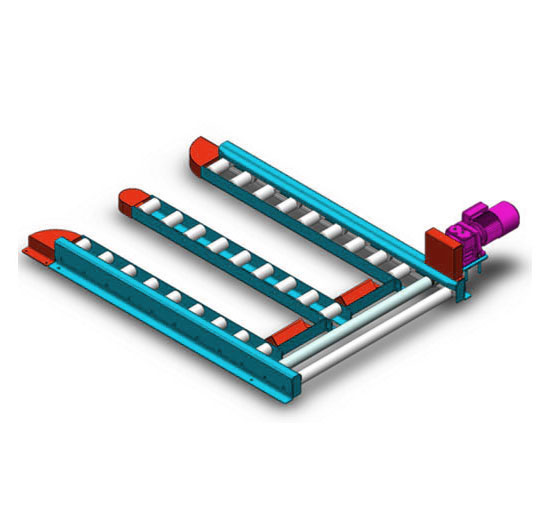

Pallet grounding roller conveyor:

One. main structure and features:

Roller: 60 single side double sprocket galvanized roller, tube precision rolled welded tube. The double sprocket on one side is 08b-14t, and the bearings on both ends of the roller are maintenance-free deep groove ball bearings.

Body: the frame is made of cold-formed steel. The frame is fixed with the ground by expansion bolts.

Guide rail: it is made of 4mm cold-formed steel and is bolted to the frame.

Drive chain: according to GB1243 standard (08b-1 precision roller chain.

Driving device: the deceleration motor is mounted on the bracket on the side of the frame. It includes a base motor with a driving sprocket. The chain is connected with the motor sprocket and two adjacent roller sprocket, and then the roller sprocket is connected with other driving rollers successively through the closed ring chain.

Protective cover: roller chain drive and motor chain drive part enclosed protective cover.

Accessory device: photoelectric support.

Surface coating: steel wire brush and sandpaper are used to remove rust on the parts of the frame, support legs and photoelectric support mounting board, and acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. Resin thickness between 60 m-90 m fasteners.

Two. Main performance and parameters:

| Description Double chain roller (08 b - 14 z) Φ 60 x 2 mm Double-sided plate guide Frame steel 125×70×5mm Drum spacing 152.4mm R series side mounted motor |

Type | |

Standard | Standard |

Length(mm) | 750 ≤ L ≤ 3000 |

Height (mm) | H(min)≥80 |

Inner width B (mm) | 620 ≤ B ≤ 1620 |

Motor power P (kw) | 0.37~0.75 |

Delivery speed V (m/min) | V=12 V=16 V=18 |

Machine load (Kg) | Max ≤1500Kg |

Carrier load (Kg) | Max ≤1200Kg |