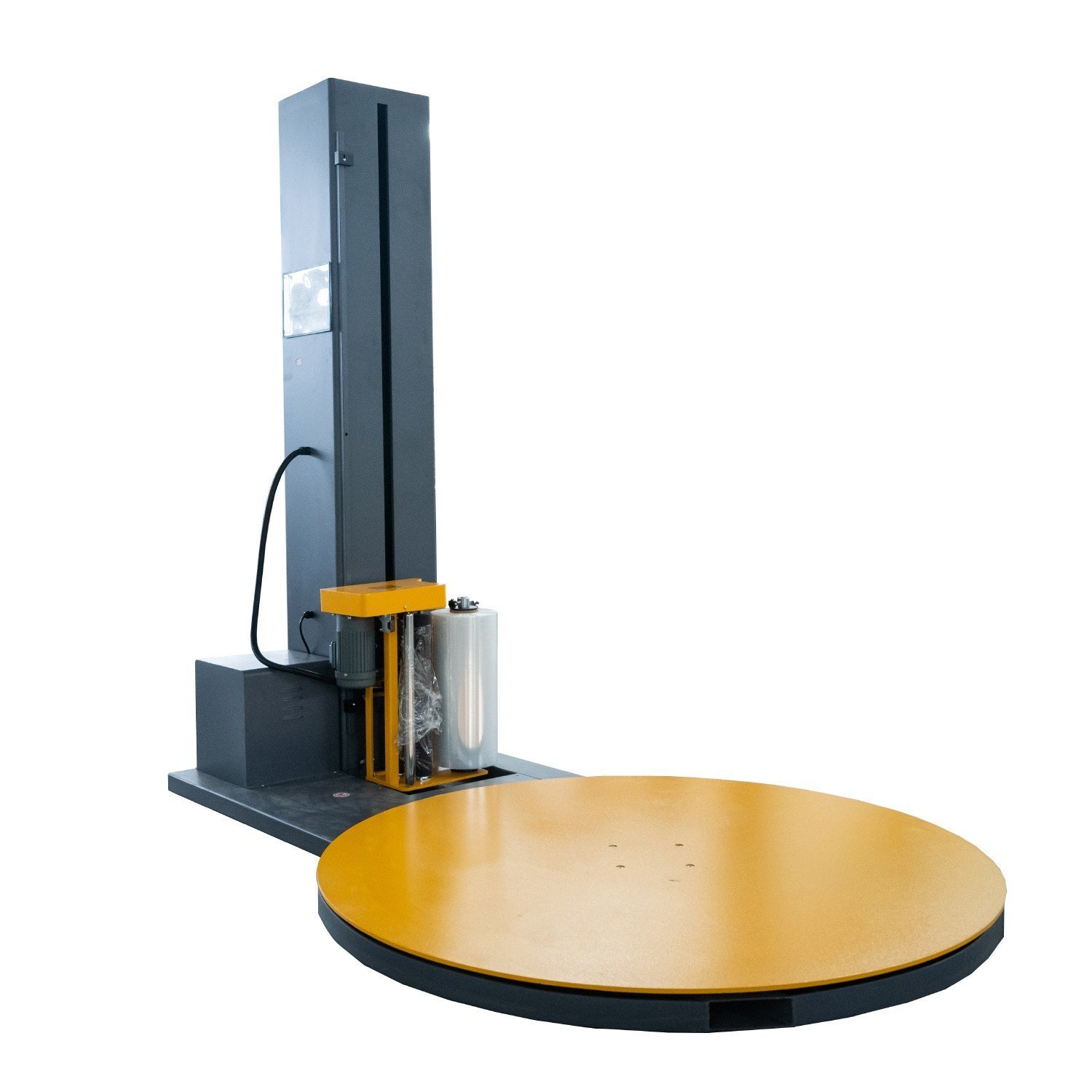

Users who are familiar with pallet winder know that pallet wrapper is generally equipped with 3 motors, turntable motor, film frame rising and falling motor and film output motor. In most of the pallet wrapper in the market, the film discharge motor is DC motor, mainly because of cost saving, while Axiomtek adopts AC inverter motor, which is also equipped with frequency converter to realize the frequency speed regulation of film discharge. Recently, there are some users feedback that the film motor of other brands always burns out, and they ask YUPACK what is the reason for that. Today,YUPACK will share with you the reasons why the film motor of the wrapping machine always burns out according to the past experience.

In fact, the reason why the motor is bad is very simple, it must be overloaded, then in addition to the overload caused by factors such as current and power supply (power overload, the machine has an overload protector), there is another situation that will cause overload, that is, the customer adjusts the speed of film output very low. Common sense says that the film speed should be matched with the rotary speed to achieve a perfect match, but the winding film used by many users is not in line with the standard of the machine film, so the film speed can not be adjusted too fast, too fast his film will break. This causes the film-feeding motor to keep running on the limit of low speed, which causes the motor to burn out over time.

It can be seen that it is reasonable to match a good horse with a good saddle. When using an automated pallet winder, you should use the corresponding consumables, and you can't use low-quality consumables just because you want to save costs, which to a certain extent also results in a waste of resources, and at the same time reduces the productivity, which is more than worth the loss!